In the race to draw down greenhouse gas emissions around the world, scientists at MIT are looking to carbon-capture technologies to decarbonize the most stubborn industrial emitters.

Steel, cement, and chemical manufacturing are especially difficult industries to decarbonize, as carbon and fossil fuels are inherent ingredients in their production. Technologies that can capture carbon emissions and convert them into forms that feed back into the production process could help to reduce the overall emissions from these “hard-to-abate” sectors.

But thus far, experimental technologies that capture and convert carbon dioxide (CO2) do so as two separate processes that themselves require a huge amount of energy to run. The MIT team is looking to combine the two processes into one integrated and far more energy-efficient system that could potentially run on renewable energy to both capture and convert CO2 from concentrated, industrial sources.

In a study reported in ACS Catalysis, the researchers reveal the hidden functioning of how CO2 can be both captured and converted through a single electrochemical process. The process involves using an electrode to attract CO2 released from a sorbent and to convert it into a reduced, reusable form.

Others have reported similar demonstrations, but the mechanisms driving the electrochemical reaction have remained unclear. The MIT team carried out extensive experiments to determine that driver, and found that, in the end, it came down to the partial pressure of CO2. In other words, the more pure CO2 that makes contact with the electrode, the more efficiently the electrode can capture and convert the molecule.

Knowledge of this main driver, or “active species,” can help scientists tune and optimize similar electrochemical systems to efficiently capture and convert CO2 in an integrated process.

The study’s results imply that, while these electrochemical systems would probably not work for very dilute environments (for instance, to capture and convert carbon emissions directly from the air), they would be well-suited to the highly concentrated emissions generated by industrial processes, particularly those that have no obvious renewable alternative.

“We can and should switch to renewables for electricity production. But deeply decarbonizing industries like cement or steel production is challenging and will take a longer time,” says study author Betar Gallant, the Class of 1922 Career Development Associate Professor at MIT. “Even if we get rid of all our power plants, we need some solutions to deal with the emissions from other industries in the shorter term, before we can fully decarbonize them. That’s where we see a sweet spot, where something like this system could fit.”

The study’s MIT co-authors are lead author and postdoc Graham Leverick and graduate student Elizabeth Bernhardt, along with Aisyah Illyani Ismail, Jun Hui Law, Arif Arifutzzaman, and Mohamed Kheireddine Aroua of Sunway University in Malaysia.

Breaking bonds

Carbon-capture technologies are designed to capture emissions, or “flue gas,” from the smokestacks of power plants and manufacturing facilities. This is done primarily using large retrofits to funnel emissions into chambers filled with a “capture” solution—a mix of amines, or ammonia-based compounds, that chemically bind with CO2, producing a stable form that can be separated out from the rest of the flue gas.

High temperatures are then applied, typically in the form of fossil fuel–generated steam, to release the captured CO2 from its amine bond. In its pure form, the gas can then be pumped into storage tanks or underground, mineralized, or further converted into chemicals or fuels.

“Carbon capture is a mature technology, in that the chemistry has been known for about 100 years, but it requires really large installations and is quite expensive and energy-intensive to run,” Gallant notes. “What we want are technologies that are more modular and flexible and can be adapted to more diverse sources of carbon dioxide. Electrochemical systems can help to address that.”

Her group at MIT is developing an electrochemical system that both recovers the captured CO2 and converts it into a reduced, usable product. Such an integrated system, rather than a decoupled one, she says, could be entirely powered with renewable electricity rather than fossil fuel–derived steam.

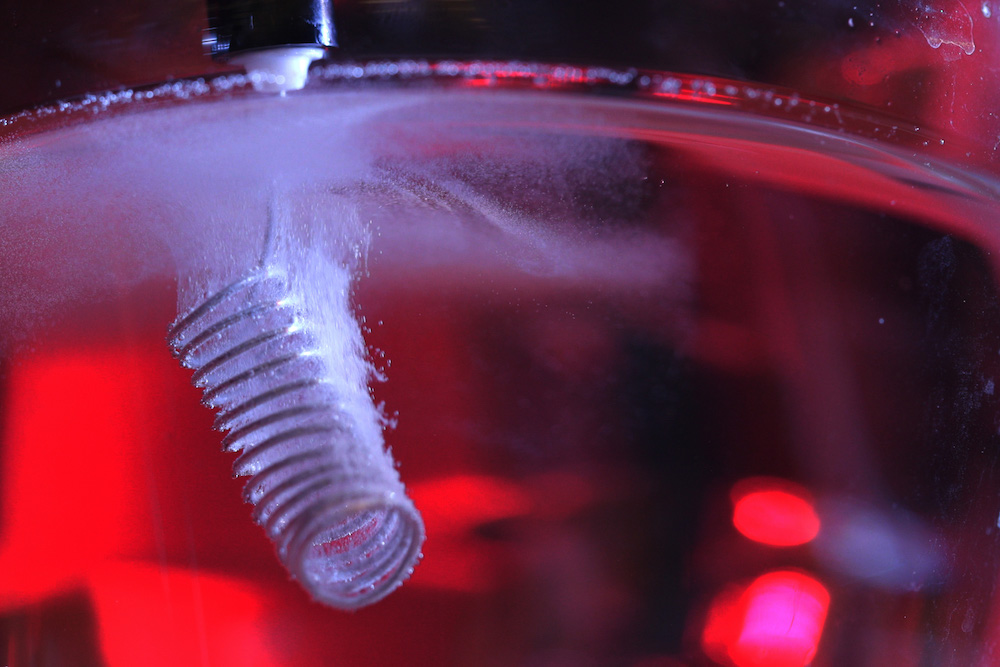

Their concept centers on an electrode that would fit into existing chambers of carbon-capture solutions. When a voltage is applied to the electrode, electrons flow onto the reactive form of CO2 and convert it to a product using protons supplied from water. This makes the sorbent available to bind more CO2, rather than using steam to do the same.

Gallant previously demonstrated this electrochemical process could work to capture and convert CO2 into a solid carbonate.

“We showed that this electrochemical process was feasible in very early concepts,” she says. “Since then, there have been other studies focused on using this process to attempt to produce useful chemicals and fuels. But there’s been inconsistent explanations of how these reactions work, under the hood.”

Solo CO2

In the new study, the MIT team took a magnifying glass under the hood to tease out the specific reactions driving the electrochemical process. In the lab, they generated amine solutions that resemble the industrial capture solutions used to extract CO2 from flue gas. They methodically altered various properties of each solution, such as the pH, concentration, and type of amine, then ran each solution past an electrode made from silver—a metal that is widely used in electrolysis studies and known to efficiently convert CO2 to carbon monoxide. They then measured the concentration of carbon monoxide that was converted at the end of the reaction, and compared this number against that of every other solution they tested, to see which parameter had the most influence on how much carbon monoxide was produced.

In the end, they found that what mattered most was not the type of amine used to initially capture CO2, as many have suspected. Instead, it was the concentration of solo, free-floating CO2 molecules, which avoided bonding with amines but were nevertheless present in the solution. This “solo-CO2” determined the concentration of carbon monoxide that was ultimately produced.

“We found that it’s easier to react this ‘solo’ CO2, as compared to CO2 that has been captured by the amine,” Leverick offers. “This tells future researchers that this process could be feasible for industrial streams, where high concentrations of carbon dioxide could efficiently be captured and converted into useful chemicals and fuels.”

“This is not a removal technology, and it’s important to state that,” Gallant stresses. “The value that it does bring is that it allows us to recycle carbon dioxide some number of times while sustaining existing industrial processes, for fewer associated emissions. Ultimately, my dream is that electrochemical systems can be used to facilitate mineralization, and permanent storage of CO2—a true removal technology. That’s a longer-term vision. And a lot of the science we’re starting to understand is a first step toward designing those processes.”

This research is supported by Sunway University in Malaysia.

This article appears in the Winter 2024 issue of Energy Futures.