In brief

Worldwide, researchers are working to adapt the standard lithium-ion battery to make versions that are better suited for use in electric vehicles because they are safer, smaller, and lighter—and still able to store abundant energy. An MIT-led study shows that as researchers consider what materials may work best in their solid-state batteries, they also may want to consider how those materials could impact large-scale manufacturing. In some cases, scaled-up production can lead to problems with resource availability or supply chains, high costs due to processing requirements or difficult battery fabrication steps, or costly measures needed to ensure high performance in the final product. Using the approach described in the MIT study, researchers can choose materials that bring the desired result in their benchtop test models while also proving suitable for large-scale production in the future.

The urgent need to cut carbon emissions is prompting a rapid move toward electrified mobility and expanded deployment of solar and wind on the electric grid. If those trends escalate as expected, the need for better methods of storing electrical energy will intensify.

“We need all the strategies we can get to address the threat of climate change,” says Elsa Olivetti PhD ’07, the Esther and Harold E. Edgerton Associate Professor in Materials Science and Engineering. “Obviously, developing technologies for grid-based storage at a large scale is critical. But for mobile applications—in particular, transportation—much research is focusing on adapting today’s lithium-ion battery to make versions that are safer, smaller, and can store more energy for their size and weight.”

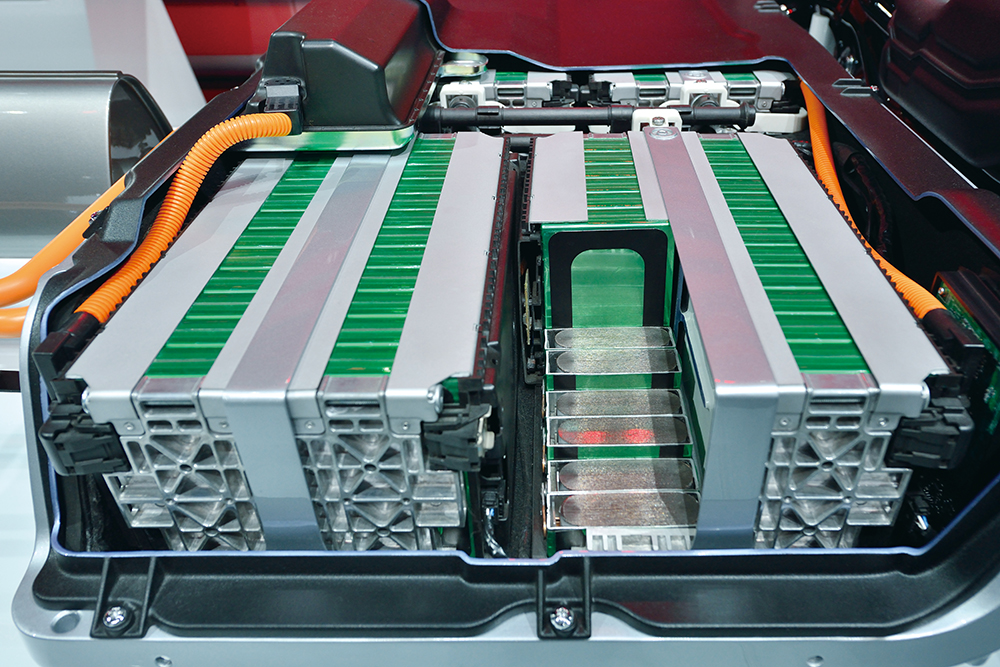

Traditional lithium-ion batteries continue to improve, but they have limitations that persist, in part because of their structure. A lithium-ion battery consists of two electrodes—one positive and one negative—sandwiched around an organic (carbon-containing) liquid. As the battery is charged and discharged, electrically charged particles (or ions) of lithium pass from one electrode to the other through the liquid electrolyte.

One problem with that design is that at certain voltages and temperatures, the liquid electrolyte can become volatile and catch fire. “Batteries are generally safe under normal usage, but the risk is still there,” says Kevin Huang PhD ’15, a research scientist in Olivetti’s group.

Another problem is that lithium-ion batteries are not well-suited for use in vehicles. Large, heavy battery packs take up space and increase a vehicle’s overall weight, reducing fuel efficiency. But it’s proving difficult to make today’s lithium-ion batteries smaller and lighter while maintaining their energy density, that is, the amount of energy they store per gram of weight.

To solve those problems, researchers are changing key features of the lithium-ion battery to make an all-solid, or “solid-state,” version. They replace the liquid electrolyte in the middle with a thin, solid electrolyte that’s stable at a wide range of voltages and temperatures. With that solid electrolyte, they use a high-capacity positive electrode and a high-capacity, lithium metal negative electrode that’s far thinner than the usual layer of porous carbon. Those changes make it possible to shrink the overall battery considerably while maintaining its energy-storage capacity, thereby achieving a higher energy density.

“Those features—enhanced safety and greater energy density—are probably the two most-often-touted advantages of a potential solid-state battery,” says Huang. He then quickly clarifies that “all of these things are prospective, hoped for, and not necessarily realized.” Nevertheless, the possibility has many researchers scrambling to find materials and designs that can deliver on that promise.

Thinking beyond the lab

Researchers have come up with many intriguing options that look promising—in the lab. But Olivetti and Huang believe that additional practical considerations may be important, given the urgency of the climate change challenge. “There are always metrics that we researchers use in the lab to evaluate possible materials and processes,” says Olivetti. Examples might include energy storage capacity and charge/discharge rate. When performing basic research—which she deems both necessary and important—those metrics are appropriate. “But if the aim is implementation, we suggest adding a few metrics that specifically address the potential for rapid scaling,” she says.

Based on industry’s experience with current lithium-ion batteries, the MIT researchers and their colleague Gerbrand Ceder, the Daniel M. Tellep Distinguished Professor of Engineering at the University of California, Berkeley, suggest three broad questions that can help identify potential constraints on future scale-up as a result of materials selection. First, with this battery design, could materials availability, supply chains, or price volatility become a problem as production scales up? (Note that the environmental and other concerns raised by expanded mining are outside the scope of this study.) Second, will fabricating batteries from these materials involve difficult manufacturing steps during which parts are likely to fail? And third, do manufacturing measures needed to ensure a high-performance product based on these materials ultimately lower or raise the cost of the batteries produced?

To demonstrate their approach, Olivetti, Ceder, and Huang examined some of the electrolyte chemistries and battery structures now being investigated by researchers. To select their examples, they turned to previous work in which they and their collaborators used text- and data-mining techniques to gather information on materials and processing details reported in the literature. From that database, they selected a few frequently reported options that represent a range of possibilities.

Materials and availability

In the world of solid inorganic electrolytes, there are two main classes of materials—the oxides, which contain oxygen, and the sulfides, which contain sulfur. Olivetti, Ceder, and Huang focused on one promising electrolyte option in each class and examined key elements of concern for each of them.

The sulfide they considered was LGPS, which combines lithium, germanium, phosphorus, and sulfur. Based on availability considerations, they focused on the germanium, an element that raises concerns in part because it’s not generally mined on its own. Instead, it’s a byproduct produced during the mining of coal and zinc.

To investigate its availability, the researchers looked at how much germanium was produced annually in the past six decades during coal and zinc mining and then at how much could have been produced. The outcome suggested that 100 times more germanium could have been produced, even in recent years. Given that supply potential, the availability of germanium is not likely to constrain the scale-up of a solid-state battery based on an LGPS electrolyte.

The situation looked less promising with the researchers’ selected oxide, LLZO, which consists of lithium, lanthanum, zirconium, and oxygen. Extraction and processing of lanthanum are largely concentrated in China, and there’s limited data available, so the researchers didn’t try to analyze its availability. The other three elements are abundantly available. However, in practice, a small quantity of another element—called a dopant—must be added to make LLZO easy to process. So the team focused on tantalum, the most frequently used dopant, as the main element of concern for LLZO.

Tantalum is produced as a byproduct of tin and niobium mining. Historical data show that the amount of tantalum produced during tin and niobium mining was much closer to the potential maximum than was the case with germanium. So the availability of tantalum is more of a concern for the possible scale-up of an LLZO-based battery.

But knowing the availability of an element in the ground doesn’t address the steps required to get it to a manufacturer. So the researchers investigated a follow-on question concerning the supply chains for critical elements—mining, processing, refining, shipping, and so on. Assuming that abundant supplies are available, can the supply chains that deliver those materials expand quickly enough to meet the growing demand for batteries?

The figure below focuses on how much the supply chains for germanium and tantalum would need to grow to meet projected demand for electric vehicles. The horizontal axis shows solid-state battery production in 2030—not in number of batteries but in the total amount of energy in gigawatt-hours (GWh) that would be needed to power a projected fleet of electric vehicles in 2030, as estimated in several industry reports.

Growth in materials supply chains needed to achieve a given solid-state battery production volume in 2030 (in gigawatt-hours) These curves show the compound annual growth rate (CAGR) of supply chains for two materials needed to meet various production levels of two types of solid-state batteries in 2030. The orange curve shows germanium, which is needed for batteries based on LGPS electrolytes, while the blue curve shows tantalum, a dopant used in making LLZO-based batteries. The horizontal dashed lines show the maximum historical CAGRs for the same two elements.

The vertical axis focuses on the amount of germanium and tantalum required for each level of solid-state battery production in 2030. The curves show the compound annual growth rate (CAGR), so the growth from year to year, needed to supply the germanium (orange) and tantalum (blue) for each level of solid-state battery production. For reference, the horizontal orange and blue dashed lines show the maximum historical CAGRs for germanium and tantalum, respectively.

As an example, an electric vehicle fleet often cited as a goal for 2030 would require production of enough batteries to deliver a total of 100 GWh. To meet that goal using just LGPS batteries, the supply chain for germanium would need to grow by 50% from year to year—a stretch, since the maximum CAGR in the past has been about 7%. Using just LLZO batteries, the supply chain for tantalum would need to grow by about 30%—a CAGR well above the historical high of about 10%.

Those examples demonstrate the importance of considering both materials availability and supply chains when evaluating different solid electrolytes for their scale-up potential. “Even when the quantity of a material available isn’t a concern, as is the case with germanium, scaling all the steps in the supply chain to match the future production of electric vehicles may require a growth rate that’s literally unprecedented,” says Huang.

Materials and processing

In assessing the potential for scale-up of a battery design, another factor to consider is the difficulty of the manufacturing process and how it may impact cost. Fabricating a solid-state battery inevitably involves many steps, and a failure at any step raises the cost of each battery successfully produced. As Huang explains, “You’re not shipping those failed batteries; you’re throwing them away. But you’ve still spent money on the materials and time and processing.”

As a proxy for manufacturing difficulty, Olivetti, Ceder, and Huang explored the impact of failure rate on overall cost for selected solid-state battery designs in their database. In one example, they focused on the oxide LLZO. LLZO is extremely brittle, and at the high temperatures involved in manufacturing, a large sheet that’s thin enough to use in a high-performance solid-state battery is likely to crack or warp.

To determine the impact of such failures on cost, they modeled four key processing steps in assembling LLZO-based batteries. At each step, they calculated cost based on an assumed yield, that is, the fraction of total units that were successfully processed without failing. With the LLZO, the yield was far lower than with the other designs they examined; and, as the yield went down, the cost of each kilowatt-hour (kWh) of battery energy went up significantly. For example, when 5% more units failed during the final cathode heating step, cost increased by about $30/kWh—a nontrivial change considering that a commonly accepted target cost for such batteries is $100/kWh. Clearly, manufacturing difficulties can have a profound impact on the viability of a design for large-scale adoption.

Materials and performance

One of the main challenges in designing an all-solid battery comes from “interfaces”—that is, where one component meets another. During manufacturing or operation, materials at those interfaces can become unstable. “Atoms start going places that they shouldn’t, and battery performance declines,” says Huang.

As a result, much research is devoted to coming up with methods of stabilizing interfaces in different battery designs. Many of the methods proposed do increase performance; and as a result, the cost of the battery in dollars per kWh goes down. But implementing such solutions generally involves added materials and time, increasing the cost per kWh during large-scale manufacturing.

To illustrate that trade-off, the researchers first examined their oxide, LLZO. Here, the goal is to stabilize the interface between the LLZO electrolyte and the negative electrode by inserting a thin layer of tin between the two. The impacts—both positive and negative—on the cost of implementing that solution are shown in the left-hand bar chart below.

Trade-off between battery performance and battery processing cost The left-hand chart shows the cost of manufacturing an LLZO-based battery without and with a thin layer of tin between the negative electrode and the electrolyte. The added tin separator increases capacity by 16 milliamp-hours per gram, which reduces unit cost, as shown by the green bar. However, the cost of including the tin layer—shown by the red bar—exceeds the savings so that the final cost is higher than the original cost. The right-hand chart shows the cost savings resulting from adding a binder material to the positive electrode of an LPSCl solid-state battery. Adding 1% (by weight) of the binder increases capacity by 65 milliamp-hours per gram and brings a $300 drop in unit cost. Since adding the binder costs almost nothing (the red bar), the full reduction in cost is achieved.

The blue bar on the left is the baseline unit cost (in dollars per kWh) of this LLZO-based battery without the layer of tin. The green bar to the right shows the decrease in cost that resulted from the improved performance (noted in the caption). The red bar shows the increase in cost due to the added materials and deposition of the tin layer using a process called sputtering. The right-hand blue bar shows the final cost per kWh, which is higher than the starting cost. So the solution to the instability problem that looked promising in the lab would actually make the battery more, rather than less, expensive during manufacturing.

In another analysis, the researchers looked at a sulfide electrolyte called LPSCl, which consists of lithium, phosphorus, and sulfur with a bit of added chlorine. In this case, the positive electrode incorporates particles of the electrolyte material—a method of ensuring that the lithium ions can find a pathway through the electrolyte to the other electrode. However, the added electrolyte particles are not compatible with other particles in the positive electrode—another interface problem. In this case, a standard solution is to add a “binder,” another material that makes the particles stick together.

The right-hand chart shows the impacts on cost of implementing that solution during manufacturing. The left-hand blue bar is the cost per kWh of manufacturing the LPSCl-based battery without the added binder. As a result of its poor performance, the cost is more than $500/kWh. The green bar shows the impacts of adding the binder. Performance increases significantly, and the cost drops by almost $300/kWh. The red bar represents the cost of adding 1% (by weight) of binder—a cost so low that the red bar is difficult to see. As the right-hand blue bar shows, essentially all of the cost decrease resulting from adding the binder is realized. The method implemented to solve the interface problem pays off in lower costs.

The researchers performed similar studies of other promising solid-state batteries reported in the literature, and their results were consistent: The choice of battery materials and processes can affect not only near-term outcomes in the lab but also the feasibility and cost of manufacturing the proposed solid-state battery at the scale needed to meet future demand. The results also showed that considering all three factors together—availability, processing needs, and battery performance—is important because there may be collective effects and trade-offs involved.

Olivetti is proud of the range of concerns the team’s approach can probe. But she stresses that it’s not meant to replace traditional metrics used to guide materials and processing choices in the lab. “Instead, it’s meant to complement those metrics by also looking broadly at the sorts of things that could get in the way of scaling”—an important consideration given what Huang calls “the urgent ticking clock” of clean energy and climate change.

This research was supported by the Seed Fund Program of the MIT Energy Initiative (MITEI) Low-Carbon Energy Center for Energy Storage; by Shell, a Founding Member of MITEI; and by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy, Vehicle Technologies Office, under the Advanced Battery Materials Research Program. The text mining work was supported by the National Science Foundation, the Office of Naval Research, and MITEI. On January 28, 2021, Elsa Olivetti was appointed associate director of the newly formed MIT Climate and Sustainability Consortium. Gerbrand Ceder is a professor in the Department of Materials Science and Engineering at the University of California, Berkeley, and a senior faculty scientist at Lawrence Berkeley National Laboratory, where he leads several research programs on resource-friendly and safe energy storage technologies. Further information about this research can be found in:

K.J. Huang, G. Ceder, and E.A. Olivetti. “Manufacturing scalability implications of materials choice in inorganic solid-state batteries.” Joule, vol. 5, issue 3, December 23, 2020. Online: doi.org/10.1016/j.joule.2020.12.001.

R. Mahbub, K. Huang, Z. Jensen, Z.D. Hood, J.L.M. Rupp, and E.A. Olivetti. “Text mining for processing conditions of solid-state battery electrolytes.” Electrochemistry Communications, vol. 121, December 2020. Online: doi.org/10.1016/j.elecom.2020.106860.

This article appears in the Spring 2021 issue of Energy Futures.