In brief

Jet fuel is a highly regulated mixture of different hydrocarbons. Today, there are approved commercial methods for making roughly three quarters of that mixture from renewable sources such as biomass. But despite extensive research, the other quarter still must come from fossil fuels. Now, an MIT-led team has demonstrated a technique that may make it possible to get that last quarter from biomass, in particular, from lignin, a component of plant material that is typically discarded as waste during biofuel production. The technique calls for reacting the biomass over a carefully selected catalyst to extract the lignin and break it down into a stable oil. Then, inside a custom-built reactor, the oil comes into contact with a different catalyst. The product that forms displays the same behavior and properties as the fossil fuel–derived hydrocarbons that now make up the last quarter of the jet fuel mixture. If this product passes some final rigorous tests for jet-fuel certification, the result could be—at last—an aviation fuel that’s 100% sustainable.

In 2021, nearly a quarter of the world’s carbon dioxide emissions came from the transportation sector, with aviation being a significant contributor. While the growing use of electric vehicles is helping to clean up ground transportation, today’s batteries can’t compete with fossil fuel–derived liquid hydrocarbons in terms of energy delivered per pound of weight—a major concern when it comes to flying. Meanwhile, based on projected growth in travel demand, consumption of jet fuel is projected to double between now and 2050—the year by which the international aviation industry has pledged to be carbon neutral.

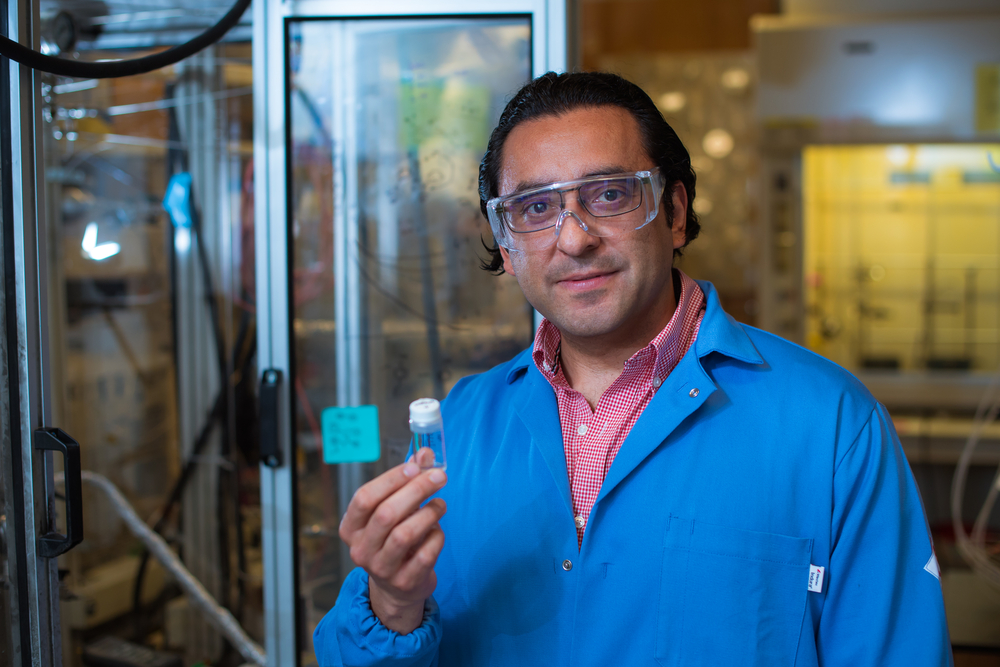

Many groups have targeted a 100% sustainable hydrocarbon fuel for aircraft, but without much success. Part of the challenge is that aviation fuels are so tightly regulated. “This is a subclass of fuels that has very specific requirements in terms of the chemistry and the physical properties of the fuel because you can’t risk something going wrong in an airplane engine,” says Yuriy Román-Leshkov, the Robert T. Haslam (1911) Professor of Chemical Engineering. “If you’re flying at 30,000 feet, it’s very cold outside, and you don’t want the fuel to thicken or freeze. That’s why the formulation is very specific.”

Aviation fuel is a combination of two large classes of chemical compounds. Some 75% to 90% of it is made up of “aliphatic” molecules, which consist of long chains of carbon atoms linked together. “This is similar to what we would find in diesel fuels, so it’s a classic hydrocarbon that is out there,” explains Román-Leshkov. The remaining 10% to 25% consists of “aromatic” molecules, each of which includes at least one ring made up of six connected carbon atoms.

In most transportation fuels, aromatic hydrocarbons are viewed as a source of pollution, so they’re removed as much as possible. However, in aviation fuels, some aromatic molecules must remain because they set the necessary physical and combustion properties of the overall mixture. They also perform one more critical task: They ensure that seals between various components in the aircraft’s fuel system are tight. “The aromatics get absorbed by the plastic seals and make them swell,” explains Román-Leshkov. “If for some reason the fuel changes, so can the seals, and that’s very dangerous.”

As a result, aromatics are a necessary component—but they’re also a stumbling block in the move to create sustainable aviation fuels, or SAFs. Companies know how to make the aliphatic fraction from inedible parts of plants and other renewables, but they haven’t yet developed an approved method of generating the aromatic fraction from sustainable sources. As a result, there’s a “blending wall,” explains Román-Leshkov. “Since we need that aromatic content—regardless of its source—there will always be a limit on how much of the sustainable aliphatic hydrocarbons we can use without changing the properties of the mixture.” He notes a similar blending wall with gasoline. “We have a lot of ethanol, but we can’t add more than 10% without changing the properties of the gasoline. In fact, current engines can’t handle even 15% ethanol without modification.”

No shortage of renewable source material—or attempts to convert it

For the past five years, understanding and solving the SAF problem has been the goal of research by Román-Leshkov and his MIT team—Michael L. Stone PhD ’21, Matthew S. Webber, and others—as well as their collaborators at Washington State University, the National Renewable Energy Laboratory (NREL), and the Pacific Northwest National Laboratory. Their work has focused on lignin, a tough material that gives plants structural support and protection against microbes and fungi. About 30% of the carbon in biomass is in lignin, yet when ethanol is generated from biomass, the lignin is left behind as a waste product.

Despite valiant efforts, no one has found an economically viable, scalable way to turn lignin into useful products, including the aromatic molecules needed to make jet fuel 100% sustainable. Why not? As Román-Leshkov says, “It’s because of its chemical recalcitrance.” It’s difficult to make it chemically react in useful ways. As a result, every year millions of tons of waste lignin are burned as a low-grade fuel, used as fertilizer, or simply thrown away.

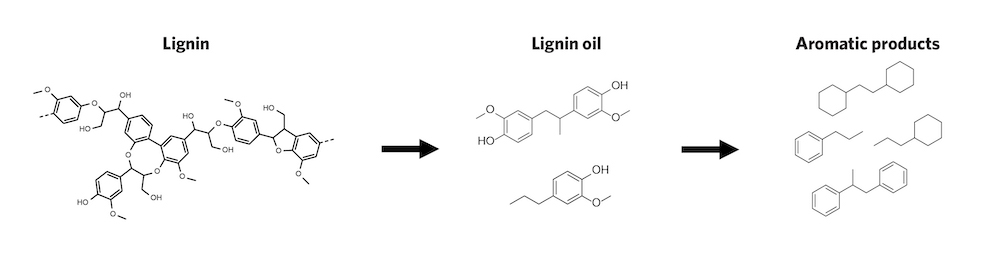

Understanding the problem requires understanding what’s happening at the atomic level. The left-hand diagram in the figure below shows the chemical structure of a single lignin molecule—the starting point of the challenge. This big “macromolecule” is made up of a network of many aromatic rings connected by oxygen (O) and hydrogen (H) atoms. (Unlabeled corners indicate carbon atoms, and the aromatic rings are recognizable by their hexagonal shape with three short lines inside.) Put simply, the key to converting lignin into the aromatic fraction of SAF is to break that macromolecule into smaller pieces while in the process getting rid of all of the oxygen atoms.

Converting molecules in waste biomass to aromatic molecules for sustainable aviation fuel. The left-hand diagram above shows an example of the type of large molecule that makes up lignin, a material typically discarded as waste during biomass processing. The first step in the MIT conversion technique breaks that large molecule into small fragments, as shown in the center diagram. The next two-step procedure removes the oxygen atoms while retaining the aromatic rings and the carbon “backbone” that links them together. The result is a mixture of aromatic molecules such as those that appear in the right-hand diagram—the material now needed to make aviation fuel fully sustainable.

In general, most industrial processes begin with a chemical reaction that prevents the subsequent upgrading of lignin: As the lignin is extracted from the biomass, the aromatic molecules in it react with one another, linking together to form strong networks that won’t react further. As a result, the lignin is no longer useful for making aviation fuels.

To avoid that outcome, Román-Leshkov and his team utilize another approach: They use a catalyst to induce a chemical reaction that wouldn’t normally occur during extraction. By reacting the biomass in the presence of a ruthenium-based catalyst, they are able to remove the lignin from the biomass and produce a black liquid called lignin oil. That product is chemically stable, meaning that the aromatic molecules in it will no longer react with one another.

As shown in the middle diagram above, they’ve now successfully broken the original lignin macromolecule into fragments that contain just one or two aromatic rings each. However, while the isolated fragments don’t chemically react, they still contain oxygen atoms. Therefore, one task remains: finding a way to remove the oxygen atoms.

In fact, says Román-Leshkov, getting from the molecules in the middle diagram to the targeted molecules such as those shown in the right-hand diagram required them to accomplish three things in a single step: They needed to selectively break the carbon-oxygen bonds to free the oxygen atoms; they needed to avoid incorporating non-carbon atoms into the aromatic rings (for example, atoms from the hydrogen gas that must be present for all of the chemical transformations to occur); and they needed to preserve the carbon backbone of the molecule, that is, the series of linked carbon atoms that connect the aromatic rings that remain.

Ultimately, Román-Leshkov and his team found a special ingredient that would do the trick: a molybdenum carbide catalyst. “It’s actually a really amazing catalyst because it can perform those three actions very well,” says Román-Leshkov. “In addition to that, it’s extremely resistant to poisons. Plants can contain a lot of components like proteins, salts, and sulfur, which often poison catalysts so they don’t work anymore. But molybdenum carbide is very robust and isn’t strongly influenced by such impurities.”

Trying it out on lignin from poplar trees

To test their approach in the lab, the researchers first designed and built a specialized “trickle-bed” reactor, a type of chemical reactor in which both liquids and gases flow downward through a packed bed of catalyst particles. They then obtained biomass from a poplar, a type of tree known as an “energy crop” because it grows quickly and doesn’t require a lot of fertilizer.

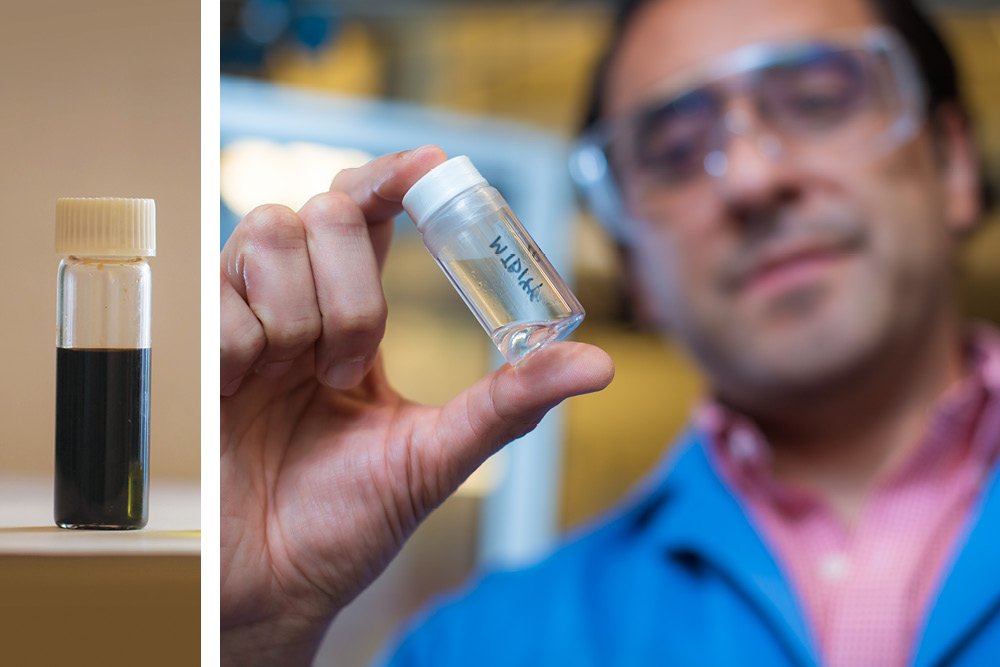

To begin, they reacted the poplar biomass in the presence of their ruthenium-based catalyst to extract the lignin and produce the lignin oil. They then flowed the oil through their trickle-bed reactor containing the molybdenum carbide catalyst. The mixture that formed contained some of the targeted product but also a lot of others that still contained oxygen atoms.

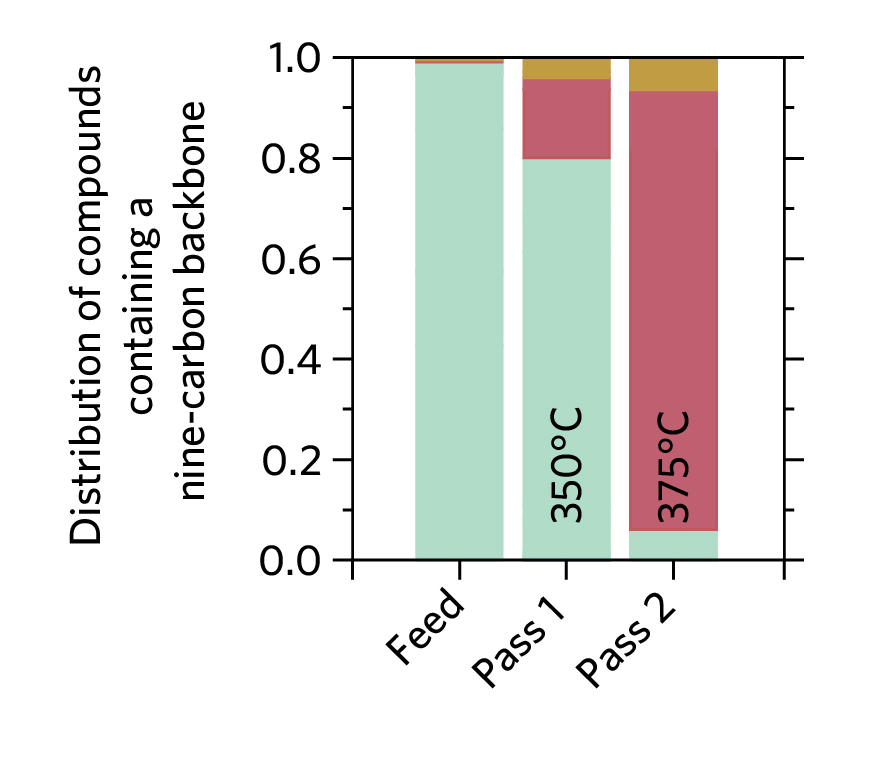

Román-Leshkov notes that in a trickle-bed reactor, the time during which the lignin oil is exposed to the catalyst depends entirely on how quickly it drips down through the packed bed. To increase the exposure time, they tried passing the oil through the same catalyst twice. However, the distribution of products that formed in the second pass wasn’t as they had predicted based on the outcome of the first pass.

With further investigation, they figured out why. The first time the lignin oil drips through the reactor, it deposits oxygen onto the catalyst. The deposition of the oxygen changes the behavior of the catalyst such that certain products appear or disappear—with the temperature being critical. “The temperature and oxygen content set the condition of the catalyst in the first pass,” says Román-Leshkov. “Then, on the second pass, the oxygen content in the flow is lower, and the catalyst can fully break the remaining carbon-oxygen bonds.” The process can thus operate continuously: Two separate reactors containing independent catalyst beds would be connected in series, with the first pretreating the lignin oil and the second removing any oxygen that remains.

Converting lignin oil from poplar biomass into products. To generate the aromatics needed for fully sustainable aviation fuel, the researchers ran the lignin oil formed during the first step of their process twice through particles of a molybdenum carbide catalyst. To analyze their results, they tracked compounds containing nine-carbon backbones—the most abundant compounds in the starting oil due to the inherent structure of lignin. This chart shows the distribution of those compounds in the oil and then how that distribution changes as a result of two sequential passes at the temperatures indicated. Green represents oxygen-containing molecules such as those shown in the center panel of the “converting molecules” figure above. Red represents the targeted aromatic products, while gold indicates other jet-fuel aliphatic molecules that form. The temperatures used in this example—350°C for the first pass and 375°C for the second—produced the best outcome, generating stable carbon yields higher than had been seen before.

The bar chart above presents results from an experiment involving lignin oil from poplar biomass running under optimized conditions: 350°C in the first step and 375°C in the second step. The distributions of different chemical compounds are indicated by color. Red represents the desired product—aromatic hydrocarbons such as those shown in the right-hand panel of the “converting molecules” figure. Green represents oxygen-containing molecules such as those shown in the center panel of the same figure. Gold shows other aliphatic jet-fuel molecules that form. Under those optimized conditions, the catalyst remains stable while generating more than 87% (by weight) of aromatic molecules.

“When we do our chemistry with the molybdenum carbide catalyst, our total carbon yields are nearly 85% of the theoretical carbon yield,” says Román-Leshkov. “In most lignin-conversion processes, the carbon yields are very low, on the order of 10%. That’s why the catalysis community got very excited about our results—because people had not seen carbon yields as high as the ones we generated with this catalyst.”

There remains one key question: Does the mixture of components that forms have the properties required for aviation fuel? “When we work with these new substrates to make new fuels, the blend that we create is different from standard jet fuel,” says Román-Leshkov. “Unless it has the exact properties required, it will not qualify for certification as jet fuel.”

To check their products, Román-Leshkov and his team send samples to Washington State University, where a team operates a combustion lab devoted to testing fuels. Results from initial testing of the composition and properties of the samples have been encouraging. Based on the composition and published prescreening tools and procedures, the researchers have made initial property predictions for their samples, and they looked good. For example, the freezing point, viscosity, and threshold sooting index are predicted to be lower than the values for conventional aviation aromatics. (In other words, their material should flow more easily and be less likely to freeze than conventional aromatics while also generating less soot in the atmosphere when they burn.) Overall, the predicted properties are near to or more favorable than those of conventional fuel aromatics.

The two vials shown above contain products from key steps in the MIT procedure. The brown lignin oil in the left-hand vial formed when the biomass was exposed to the first catalyst. The clear liquid in the right-hand vial—here displayed by Professor Román-Leshkov—formed when the lignin oil passed though the trickle-bed reactor for the second time. Now free of oxygen molecules, it is the aromatic fraction needed to make today’s aviation fuel 100% sustainable. Credit: Gretchen Ertl

Next steps

The researchers are continuing to study how their sample blends behave at different temperatures and, in particular, how well they perform that key task: soaking into and swelling the seals inside jet engines. “These molecules are not the typical aromatic molecules that you use in jet fuel,” says Román-Leshkov. “Preliminary tests with sample seals show that there’s no difference in how our lignin-derived aromatics swell the seals, but we need to confirm that. There’s no room for error.”

In addition, he and his team are working with their NREL collaborators to scale up their methods. NREL has much larger reactors and other infrastructure needed to produce large quantities of the new sustainable blend. Based on the promising results thus far, the team wants to be prepared for the further testing required for the certification of jet fuels. In addition to testing samples of the fuel, the full certification procedure calls for demonstrating its behavior in an operating engine—”not while flying, but in a lab,” clarifies Román-Leshkov. In addition to requiring large samples, that demonstration is both time-consuming and expensive—which is why it’s the very last step in the strict testing required for a new sustainable aviation fuel to be approved.

Román-Leshkov and his colleagues are now exploring the use of their approach with other types of biomass, including pine, switchgrass, and corn stover (the leaves, stalks, and cobs left after corn is harvested). But their results with poplar biomass are promising. If further testing confirms that their aromatic products can replace the aromatics now in jet fuel, “the blending wall could disappear,” says Román-Leshkov. “We’ll have a means of producing all the components in aviation fuel from renewable material, potentially leading to aircraft fuel that’s 100% sustainable.”

Postdoc Jamison Watson joined the Román Lab in January 2021 to focus on the catalytic upgrading and conversion of lignin into the aromatic fraction needed to make aviation fuel fully sustainable. Here, he adjusts the trickle-bed reactor to optimize its performance. In related research, he is working to further improve product yields by breaking apart molecules in the mixture that are still too large for use in sustainable aviation fuels. Credit: Gretchen Ertl

This research was initially funded by the Center for Bioenergy Innovation, a U.S. Department of Energy (DOE) Research Center supported by the Office of Biological and Environmental Research in the DOE Office of Science. More recent funding came from the DOE Bioenergy Technologies Office and from Eni S.p.A. through the MIT Energy Initiative. Michael L. Stone PhD ’21 is now a postdoctoral scholar in chemical engineering at Stanford University. Matthew S. Webber is a graduate student in the Román-Leshkov group, now on leave for an internship at the National Renewable Energy Laboratory. More information about this research can found in:

M.L. Stone, M.S. Webber, W.P. Mounfield III, D.C. Bell, E. Christensen, A.R.C. Morais, Y. Li, E.M. Anderson, J.S. Heyne, G.T. Beckham, and Y. Román-Leshkov. “Continuous hydrodeoxygenation of lignin to jet-range aromatic hydrocarbons.” Joule, October 2022. Online: doi.org/10.1016/j.joule.2022.08.005.

This article appears in the Spring 2023 issue of Energy Futures.