MIT researchers and their collaborators from South Africa and England have demonstrated that it is possible to create elegant, energy-efficient buildings with little energy consumption and essentially no energy-intensive materials.

Their project, located in rural South Africa, used local workers, local materials (mostly soil), a 600-year-old vaulting technology, and a quarter of the energy usually used in materials and in the construction process. The striking new building—which requires almost no energy to run—is a model for sustainable construction worldwide.

As the world struggles to reduce energy consumption and greenhouse gas (GHG) emissions, much attention is focusing on making buildings—both existing and new—operate more efficiently. But John Ochsendorf, associate professor of building technology, thinks mostly about another, less-recognized aspect of the built environment: the “embodied energy” of buildings, that is, the energy consumed in construction, including the entire life cycle of the materials used, from the extraction of raw materials to the manufacture, transportation, and installation of products at the building site.

Most people assume that the embodied energy of a building is small compared to the energy used in operating it over its lifetime. “Conventional wisdom says that the operating energy is far more important than the embodied energy because buildings have a long life—maybe a hundred years,” says Ochsendorf. “But we have office buildings in Boston that are torn down after only 20 years.” While others may view buildings as essentially permanent, he views them as “waste in transit.”

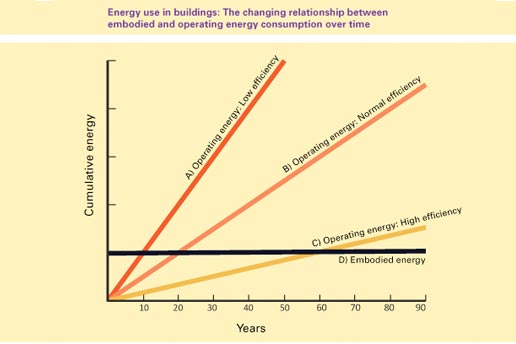

The illustrative graph in the right-hand column conveys his point. The lines labeled A through C show cumulative energy consumption over almost a century assuming varying levels of operating efficiency. Line D is embodied energy. (In reality, embodied energy would rise slightly over time due to refurbishments and renovations.)

Assuming normal operating efficiency (line B), the amount of energy needed to build the house equals the amount used in operating it for about 20 years. In other words, if the house lasts 20 years, the total energy consumed is half from building it and half from operating it. At 40 years, one-third of its lifetime energy goes to building it, two-thirds to operating it. And so on.

A comparison of lines A, B, and C shows that as buildings become more efficient and the energy needed to operate them drops, the embodied energy becomes relatively more important. Line C shows the extreme: a highly efficient house with very low cumulative operating energy. In this case, the embodied energy will be several times the cumulative operating energy for the first 20 years. Indeed, it will be 60 years before the operating energy equals the embodied energy.

Several construction industry conventions contribute to high embodied energy. Architects and structural engineers are typically taught to design with steel and reinforced concrete—materials that are energy intensive and have high associated carbon dioxide (CO2) emissions. Currently, about 7% of anthropogenic CO2 emissions is attributed to the production of cement, the primary ingredient in concrete. And the escalating consumption of cement and steel raises concerns about resource use as well as energy and emissions.

Another problem is the conventional design process in which experts in different disciplines work one after another on a given project. In such a process, designers may make energy-inefficient decisions early on, and then engineers try to improve things by making minor changes afterwards. “It’s like having a Hummer and putting solar panels on it or inflating the tires to improve its gasoline consumption,” says Ochsendorf. “Every bit helps, but the original design is poor.”

A better approach is to have architects, engineers, clients, and others work together from the beginning to come up with a good design—a “whole life” design that takes account of construction, use, and demolition. Materials with high embodied energy can be used, but only when they offer special advantages. Aluminum, for example, has high embodied energy; but if it performs well, does not corrode, lasts for a long time, and can be salvaged and recycled during demolition, then it can be a good choice for certain applications.

A truly sustainable design should aim for what Ochsendorf and others call the triple bottom line: it should make sense economically, environmentally, and socially. Thus, it should cost less; it should minimize carbon emissions, energy use, and resource consumption; and it should fit into and support the local community.

In Ochsendorf’s view, those constraints need not stifle creativity; rather, they can create an opportunity for innovative thinking and for finding novel answers and solutions.

Innovative design for the developing world

As an illustration of innovative thinking under extreme constraints, Ochsendorf describes a project in which he and his students have been involved: the construction of the Mapungubwe National Park Interpretive Centre in a World Heritage Site in South Africa.

Many developing nations want modern glass-and-steel buildings designed and built by teams imported from other parts of the world. In contrast, the South African National Park Service—the sponsor of the Mapungubwe project—called for its new interpretive centre to be built by local people using local materials, with minimal environmental impact and low electricity demand. Ancillary benefits should be reducing poverty in the area and empowering the local people with new skills and experience.

In collaboration with colleagues at Cambridge University, England, and architects and engineers in South Africa, Ochsendorf and his students took on the challenge. The team designed and built an innovative building that not only meets the demands of the South African government but also recently won an award from the Holcim Foundation for Sustainable Construction in the region of Africa and the Middle East.

Their project combines a well-known, “humble” material—soil—with a structural system based on historical technology.

Key to their design are bricks, or tiles, made from soil and a little cement (about 5% by mass). The tiles are made by local workers who put the soil-cement mixture plus water into a form and compact it using a long lever arm. The result: handmade tiles consisting mostly of mud.

For the building’s design, Ochsendorf brought to bear his other research specialty: the study of historical design and traditional building methods. He and his colleagues turned to a 600-year-old Mediterranean technique called “tile vaulting,” a construction system that uses thin bricks to create lightweight and durable buildings.

But instead of using fired clay bricks (which require a lot of energy for baking), they chose to make the vaults out of the mud tiles, which are relatively weak. If the form of the vaults is not structurally optimal, the weak mud bricks would not be able to support the weight of the building.

So they used new MIT software to define a vault geometry that could produce a thin, safe shell using their low-strength tiles. The final design consists of several vaults and domes, including a vault with a maximum span of 60 feet, using thin shells of mud brick only 4 inches thick. The structure requires no steel reinforcement, which simplifies construction, lowers cost, and reduces the embodied energy—by fully 75% compared to a conventional building.

In addition to the tile vaults, the new centre—scheduled for completion this fall—has sandstone floors, earth block walls, and exterior stone cladding. The design maximizes natural light and natural ventilation, and the high thermal mass of the structure passively cools the space during the day and radiates accumulated heat at night. As a result, little operating energy is required.

The building is structurally sound, elegantly simple, environmentally sustainable, and aesthetically pleasing, blending naturally into the surrounding landscape. “Trying to radically save energy and materials and to minimize environmental impacts may mean challenging some of our assumptions about what we think buildings should look like,” says Ochsendorf. “But I do think the new museum is beautiful.”

The way forward

Ochsendorf believes that a critical step toward sustainable building is to establish new metrics for the industry. Instead of cost per square foot (or meter), architects, builders, clients, and the public must learn to think in energy consumption—or better still, GHG emissions—per square foot. “Think about the fluency the American public has about the miles per gallon of cars,” he says. “They understand that if you get 15 mpg, you’ve got a guzzler, and if you get 50 mpg, it’s great. We need an equivalent metric for buildings that the public understands.”

His goals for his MIT students? To be the first generation of designers to internalize those metrics into their design process and to be able to talk comfortably about the energy and emissions associated with constructing and operating their buildings.

This work was supported by the International Masonry Institute and the Cambridge-MIT Institute. Further information can be found at Masonry at MIT.

This article appears in the Spring 2009 issue of Energy Futures.