Designing energy-efficient buildings can be challenging: Incorporating features that decrease the energy needed to run them often increases the energy-intensive materials required to build them, and vice versa. Now an MIT team has demonstrated a computer simulation that can help architects optimize their designs for both future operational energy and the initial energy required for making structural materials—at the same time. The technique rapidly generates a set of designs that offer the best compromises between those two critical energy components. The architect can then make a choice based on quantitative information as well as aesthetic preference. The demonstration produced some striking results. In one case, choosing a design that was slightly less efficient in operational energy cut energy for structural materials in half—an opportunity that would have gone undetected using a simulation that optimized operational energy alone.

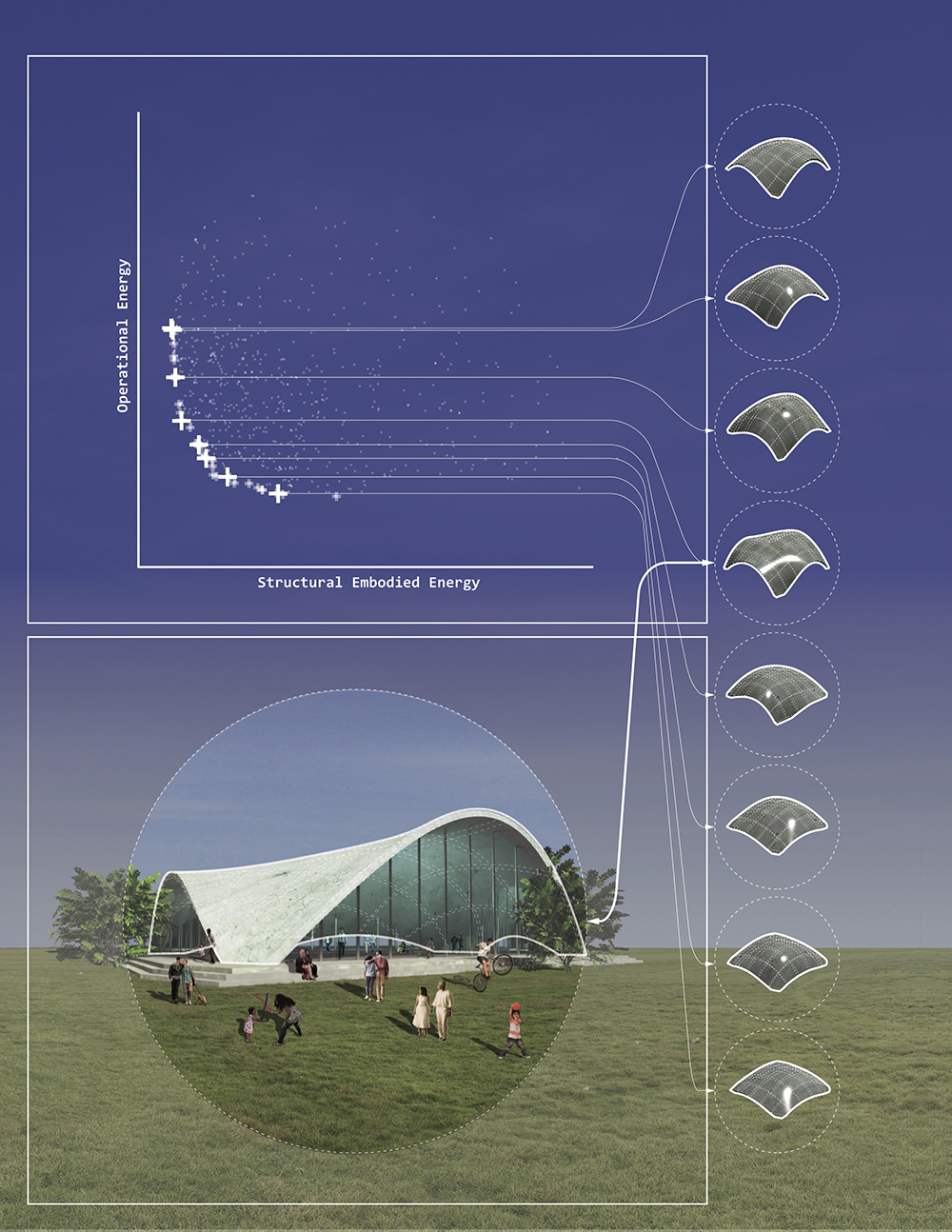

This illustration represents simulation results in which optimal design choices arise from myriad options that explore trade-offs between structural embodied energy and operational energy. Illustration: Nathan Brown, Caitlin Mueller, Kam-Ming Mark Tam, and Renaud Danhaive, MIT

In recent years, concerns about global warming and greenhouse gas emissions have prompted efforts to make buildings more sustainable, or “green.” The main focus has been on reducing the energy that buildings require for heating, cooling, ventilation, and lighting. But an increasing role is being played by “structural embodied energy,” that is, the energy used to extract, process, and transport the structural materials in them.

“Newly constructed buildings have become so efficient to operate that the energy embodied in the materials required to create them is becoming a larger and larger percentage of the total energy used,” says Caitlin Mueller, assistant professor of architecture and of civil and environmental engineering. “Energy is embodied in building materials such as finishes, insulation, and cladding, but far more is in the building’s structural system.” And while benefits from more energy-efficient operation are spread over the lifetime of the building, energy savings from reducing that structural embodied energy—notably by early decisions about a building’s overall shape—are reaped immediately.

When designing a building with energy in mind, therefore, architects need to consider both operational and structural embodied energy, and the two are intertwined. For example, extending the roof out beyond the edge of a building can shade windows and reduce cooling needs in hot climates, but making an overhang that’s structurally sound can take a lot of energy-intensive material.

The challenge is to determine a building design that trades off the two goals—and also allows room for creativity and aesthetic decisions. Today’s computer algorithms can help guide the design process, taking just seconds to generate designs that are optimized for several objectives at once. Even so, many architects and structural engineers persist in doing separate analyses, looking either to minimize operational energy consumption or to minimize the amount of energy-intensive material required. And in both cases, they tend to perform their analyses only after they have developed a conceptual design. “They use a simulation program to see if the design they’ve come up with is ‘good enough,’” says Mueller—a process she calls “guess and check.”

The changing role of simulation

Mueller and her colleague Nathan Brown SMBT ’16, now a PhD candidate in building technology, are keenly aware of the importance of focusing on structural embodied energy as well as operational energy use. Both are trained in architecture and structural engineering, and both are convinced of the power of computational design. They note in particular today’s “genetic” algorithms, which perform design optimization based on an evolutionary metaphor: They generate “populations” of designs that are “bred” and “mutated” over time for better performance. Given a starting set, the computer calculates the operational and structural embodied energy for each building design and then tweaks certain features or aspects to generate a set of new designs with better characteristics. By repeating the process, the computer analyzes thousands and thousands of designs to produce a limited set for the architect’s consideration.

“These final designs are suggested by the computer as ones that are going to do well,” says Brown. “It would be much harder to find them through trial and error, just by guessing. So I think it changes the role of simulation analysis in the design process. It’s not just a checking algorithm but is a way to actually help with creative design exploration.”

Challenging case studies

To demonstrate the power of this approach, Mueller and Brown performed a series of case studies focusing on “long-span buildings”—structures such as airport terminals, concert halls, and bus stations. Such buildings seemed a good subject for their analyses. For one thing, they pose a special modeling challenge: They often have large open spaces with unusual shapes and few interior columns, so they rely on systems of triangular trusses and frames working together to support the load of the building. The structural materials required for those systems make up a significant fraction of the embodied energy component, so they provide a good target for energy savings. In addition, the use of computer simulation early in the design process—when the shape of the building is determined—can have a major impact on embodied energy. Careful choice of the geometry and layout of the structure can reduce internal forces and decrease the amount of energy-intensive structural materials required for support.

Two characteristic features of long-span buildings involve trading off operational and structural embodied energy. Already mentioned is the cantilevered overhang, a rigid surface extending out from the main part of a building, anchored only at its origin with no additional support along its length. Adding a carefully designed overhang can block sunlight and reduce cooling loads, but it increases embodied energy by requiring the use of extra structural material.

The other aspect of interest is building height. According to Brown, increasing the height will spread out internal forces in the structure so that support systems can be thinner and more widely spaced. Making the structure taller can—up to a point—reduce the amount of building material required, and embodied energy will decline. But a taller building has more exterior surface—the “building envelope”—and a greater volume of air to be conditioned, both of which generally increase operational energy.

Building types for case studies

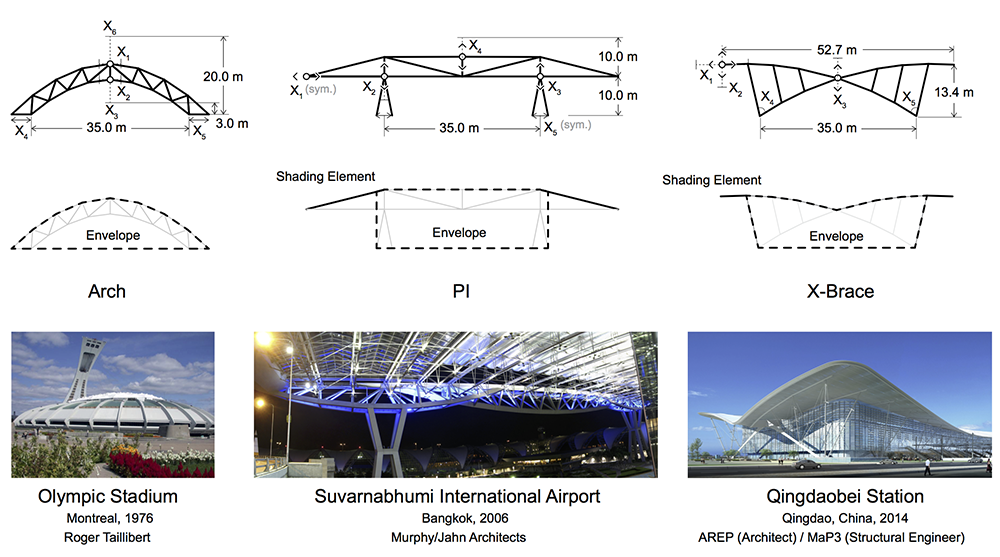

To demonstrate multi-objective optimization, MIT researchers performed analyses of the three types of long-span buildings shown above. The upper diagrams show each building’s geometry with both set and variable dimensions; the lower diagrams outline the building envelope; and the photos show representative constructed buildings. The enclosed arch involves trade-offs between operational and structural embodied energy when varying height. The PI structure and x-brace involve trade-offs associated with both height and overhang. (For complete image credits, see the Energy and Buildings citation at the end of this article.)

To test those trade-offs in practical systems, Mueller and Brown analyzed three types of long-span structures: an enclosed, trussed arch; a “PI” structure (resembling the Greek letter); and an “x-brace.” The figure above shows diagrams of the three building types along with photos of representative buildings. The upper diagrams indicate certain set dimensions along with others to be defined, while the lower diagrams include dashed outlines showing the building envelopes. Analysis of the enclosed arch demonstrates energy trade-offs involved in selecting height, while analyses of the PI structure and the x-brace show trade-offs associated with both height and overhang.

For each building type, the researchers defined a three-dimensional structure for simulation by assuming a parallel lineup of identical units to create an indoor space with a set floor area. They then ran simulations using a multi-objective genetic algorithm plus a collection of other programs to calculate operational and structural embodied energy. The former is based on energy flows for heating, cooling, lighting, ventilation, and so on. For the latter, they considered only the use of steel, a key structural material in long-span buildings. The amount of steel required is determined by calculating the load on each member of the structure and the smallest section size required to support it. The total steel in the design is computed and then converted (based on weight) into structural embodied energy using a standard coefficient. Based on those evaluations, the multi-objective optimization algorithm comes up with a new set of designs that should perform better—and the process repeats.

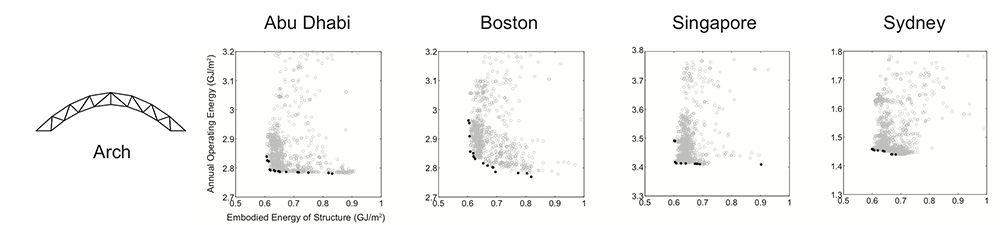

Simulation results for the analysis of the arch

These diagrams plot results for annual operational energy against structural embodied energy for the closed arch in four locations with different climates. Each dot represents a specific design generated by the computer. The dark dots on each diagram indicate a set of optimal choices where the designer can’t do better on one objective without doing worse on the other.

Simulation results

The figure above shows simulation results for the closed arch in four locations representing different climates: Abu Dhabi (arid), Boston (cool), Singapore (tropical), and Sydney (temperate). Each diagram plots annual operational energy against embodied energy of the structure, both measured in gigajoules per square meter. The individual dots on the diagrams represent specific designs generated by the computer.

The series of dark dots on each diagram forms the “Pareto front”—the best collection of compromising designs where the designer can’t make one performance objective better without making the other one worse. The dark dot at the farthest left in each diagram minimizes structural embodied energy regardless of operational energy, while the dark dot at the farthest right minimizes operational energy regardless of embodied energy. Points in between represent designs that are compromises between those objectives for a given emphasis on one objective over the other (say, minimizing operational energy more than embodied energy).

Of particular interest are the shapes of the Pareto fronts. The front for Boston is the classic shape—sometimes called a banana curve. The results are on a continuum such that moving either way will enable the user to do a bit better on one objective while doing a bit worse on the other.

In contrast, the curve for Abu Dhabi contains a long, flat section and then an abrupt 90-degree turn at a point referred to as the knee. In that case, moving left along the Pareto front will enable the user to significantly reduce embodied energy without much sacrifice in operational energy—as far as the knee, when operational energy suddenly jumps up. The point at the knee is therefore likely to be a good choice, as it provides a good balance between the two variables. “A single-objective optimization for operational energy would produce the dot farthest to the right,” says Mueller. “But by considering both objectives, we find that with just a small increase in operational energy, we can decrease embodied energy by about a factor of two.”

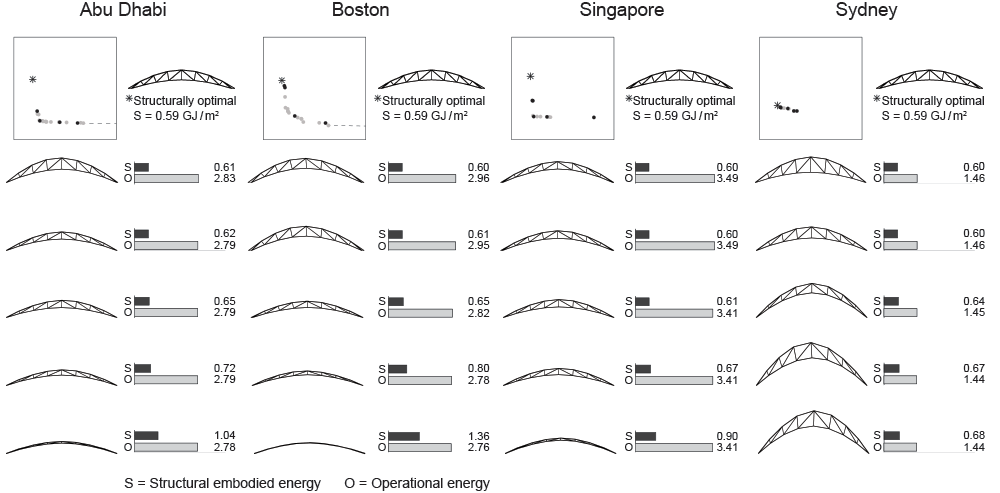

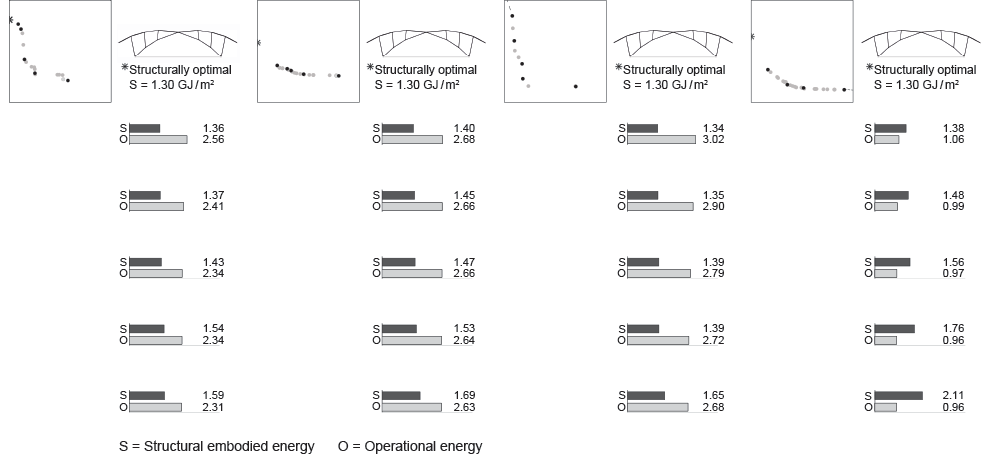

Visual catalog of the optimal set of arch geometries

These arch geometries correspond to five of the dark data points representing the best compromises in the diagrams in the previous image. The most structurally efficient designs are at the top, the most operationally efficient at the bottom. The solutions vary from city to city, with the set for Sydney looking markedly different from the others due to that city’s mild climate.

Visualizing the options

The figure above presents a “visual catalog” of the arch configurations that correspond to five selected points on the Pareto fronts in the previous image. The designs range from the most structurally efficient at the top to the most operationally efficient at the bottom. Bars beside each design indicate its structural embodied energy and operational energy, both measured in gigajoules per square meter.

The structurally efficient designs don’t differ dramatically from city to city, but the options with efficient operation do. In Abu Dhabi, Boston, and Singapore, efficient operation is achieved by decreasing the arch truss depth and height to reduce the interior conditioned volume and the envelope surface area—a change that also reduces structural efficiency. In contrast, the Sydney arch achieves higher operating efficiency by becoming taller to maximize its surface area. In the mild Sydney climate, exchanging more heat with the outside can stabilize temperatures inside.

The transition from embodied to operational energy efficiency is more gradual with the x-brace, as shown below. In Abu Dhabi and Singapore, all the solutions are fairly shallow, with small envelope surface areas and shading edges that curve down toward the windows they protect. In Boston, the main arch members become less curved, with flatter shading elements that allow more sunlight to enter and offset heating loads. In Sydney, those elements also become flat but at a higher angle, which generates taller walls and windows—again supporting greater surface area and more extensive heat exchange with the outdoors. Interestingly, in several cases the x-brace is noticeably asymmetrical so as to more effectively block out or let in the sun.

Visual catalog of the optimal set of x-brace geometries

This figure presents the optimal set of designs for the x-brace. In Abu Dhabi and Singapore, operational energy is reduced by curving the overhangs down over the windows. In Boston, those shading elements are less curved to allow more sunlight in, and in Sydney they become flat at a higher angle to generate taller walls and windows and thus more surface area to exchange heat with the mild outdoor air. In several cases, the x-brace is slightly asymmetrical to maximize the impact on incoming sunlight.

Considering other factors

The researchers think there’s more to be done with their methodology. Already they have performed a series of analyses to show how different assumptions about building lifetimes and operational efficiency can change the shape of the Pareto front. Factors such as monetary cost and constructability could also be considered and traded off. But they hope that their work to date will encourage architects and structural engineers to incorporate the MIT team’s methodology early in the design process, when it can push solutions in interesting and unexpected ways and lead to new building designs that are high-performance, innovative, and architecturally expressive.

This research was supported by the MIT Department of Architecture, including a one-semester Hyzen Fellowship awarded to Nathan Brown. Further information can be found in:

N.C. Brown. Multi-Objective Optimization for the Conceptual Design of Structures. SM thesis, MIT Department of Architecture, June 2016.

N. Brown and C.T. Mueller. “Design for structural and energy performance of long span buildings using geometric multi-objective optimization.” Energy and Buildings, vol. 127, pp. 748–761, 1 September 2016.

This article appears in the Autumn 2016 issue of Energy Futures.