Vladimir Bulović, the Fariborz Maseeh (1990) Chair in Emerging Technology, and the members of his ONE Lab have been creating next-generation, lightweight, flexible photovoltaics that could change the way the world deploys solar energy systems. He’s also the founding faculty director of MIT.nano, shepherding the evolution of MIT’s new nanoscale research facility that will support thousands of researchers from academia, startups, and industry. He recently spoke with the MIT Energy Initiative (MITEI) for a podcast episode on game-changing technologies. Below is an edited version of his conversation with Francis O’Sullivan, former director of research at MITEI and a senior lecturer at the MIT Sloan School of Management.

Q: We’ve seen dramatic reductions in the cost of panels, and we’re seeing real deployment today. There’s a tremendous amount of excitement about solar energy offering a pathway to very significant decarbonization of electricity systems. With that said, some people, including yourself, have begun to reflect on some of the inherent limitations of today’s crystalline silicon technologies. Tell us about the journey that solar has made over the past few decades—and how we can build on the momentum of the low-carbon energy transition.

A: I would start by emphasizing that the solar technology of yesterday is nothing like the solar technology of today. And the solar technology of tomorrow will be even more different.

Today’s solar panels are dramatically improved, both in lifetime and efficiency, and can be made more economically due to standardized and scaled manufacturing. Today, two-thirds of the cost of installed solar is spent on installation and only one-third on the module itself. This implies that if we can make the installation simpler, we might be able to reduce the cost of solar technology by a factor of as much as three. What does that imply for the cost of solar electricity, which today can be bought for as low as 5 cents a kilowatt-hour? Reduce it by a factor of three, and you are at less than 2 cents a kilowatt-hour. That’s remarkable. No other electricity-generating technology can reach such a low cost.

As the cost of the solar cells comes down—and as we make them easier to install—it will become obvious that a thirty-year lifetime is not a necessary requirement for installed solar modules. A ten-year lifetime will be sufficient. Costs will be low, and installation could be as simple as stapling rolls of future thin-sheet, lightweight solar modules to the roof. With lightweight solar modules you would not need to reinforce your roof, and delivery of such modules to remote parts of the world that are longing for electrical power will be much easier to do than with the present silicon. The developing world market might be the perfect stepping stone for the broader introduction of this new type of solar into the developed world. The weight of a solar module would become a very significant metric for the deployment of such technology.

I would also say that there are novel modalities that will start coming through in the use of solar. Solar as a power source is brilliant. Sunlight gives us 10,000 times more energy than we consume in the course of a year, but the challenge is collecting it all. If you can collect all the sunlight for one hour, we can power the planet for one year. The catch is that for that one hour, half of the entire planet Earth (the half facing the Sun) needs to be covered with solar cells. The challenge of such large-area deployment is quite significant.

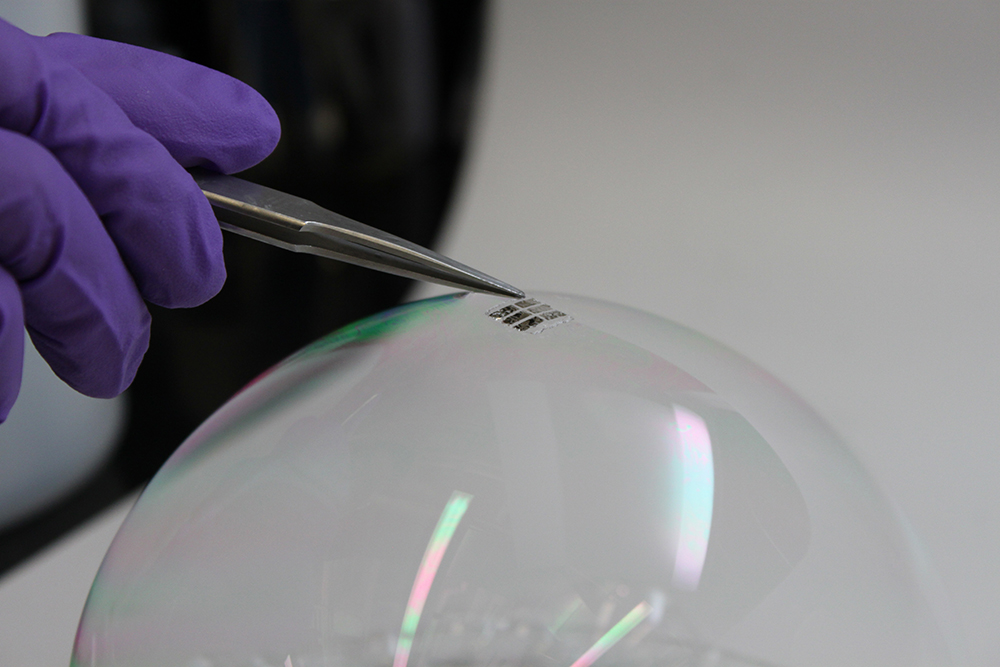

If we can generate solar activity from the surfaces of objects we already build and touch, that might be another way of deploying solar energy. But since by design solar is meant to absorb most of the incident light, a typical solar cell is very dark-looking, or it reflects blue due to the anti-reflective coating that’s on top of it. So another technology that you could consider is the so-called invisible solar cells—solar cells that do not absorb any visible light, and hence appear transparent (invisible), but do absorb infrared and ultraviolet light. These transparent solar cells are never going to work as efficiently as silicon or some of the other dark-looking cells, because we’re purposefully throwing out a third of the available spectrum (the visible spectrum). Nevertheless, the Shockley-Queisser efficiency limit on these cells is on the order of 21 percent for a single junction versus 31 percent for silicon. Yet, when you make them, they look like absolutely nothing. They look like a piece of glass.

With such transparent cells, any surface could become solar active and in a format that is unobservable, hence enabling incidental collection of power by solar windows or even your eyeglasses. With a micron-thick transparent solar coating on your eyeglasses you can, with today’s version of transparent solar cells, generate 5 to 10 milliwatts of power in a bright environment. Direct that power along the arms of your glasses toward your ears to power a set of hearing aids or a wireless earpiece, and you’ll never have to replace their batteries. If you place such a transparent cell on top of your Kindle’s screen, you would never need to charge your Kindle again. Because even with a 1 percent power-efficient version of such a transparent cell, you’ll collect enough incidental solar power in the course of a few days to fully recharge the Kindle battery for a couple of weeks.

I think that we can redefine the built environment by the introduction of the next generation of these nanostructured solar technologies, which are just coming around the corner. Although they might not be the most power-efficient solar cells, they will be more easily deployable because they’ll be just a value-added, thin-film coating on existing surfaces that we’ve already built.

Q: With your work here at MIT.nano, you are putting together a center for the Institute that’s about helping broadly expand and enable the deployment of these new technologies across this wide spectrum of opportunities and helping the innovators to access the technologies that they need to move through the development process in a way that hasn’t been available to date. How is this effort with MIT.nano becoming more and more relevant and important as we face these big challenges for technology development?

A: MIT.nano has been in the making for over a couple of decades. We built it right in the middle of our campus, right next to the MIT dome, footsteps away from everyone. It is 100,000 square feet of shared laboratory space in a 200,000-square-foot building, with tools for researchers from every department of MIT. It does not belong to a single school; it does not belong to a single department. Two thousand researchers per year will utilize it. As time goes on, it will likely grow to 3,000 to 4,000 users per year, meaning that roughly half of MIT will be stepping into MIT.nano at some point. Right now, about a quarter of MIT researchers will use MIT.nano.

Presently, much of the MIT.nano space is awaiting the installation of new equipment, inspired by new ideas from faculty and students. As a researcher at MIT, if you have a fantastic idea, you can develop it in your private lab, then figure out how to scale it. You can try building a new system inside your lab, but typically there’s no space for something like that. MIT.nano, though, does have space, and a set of complementary tools. As long as you’re willing to engage others, generate a community of people around you, you’ll be able to locate the toolsets in MIT.nano and build a grand idea together.

Then there are startups that nurture a unique set of ideas. The big challenge with startups is that ten years ago, 30 percent of the venture capital went into hardware development, as would be needed for solar development, for example. Today, less than 5 percent of the venture capital is invested in the development of hardware ideas, whereas 95 percent is invested in digital ideas. So money is sparse. If you actually want to launch a new technology from scratch using new materials and processes that have never been scaled before, a typical number when it comes to how much money you will need is about $50 million to $100 million over the course of five to ten years of scaling up the idea.

The question in my mind was, Is there a way to utilize facilities like MIT.nano to dramatically reduce the amount of money you’ll need to prototype your ideas—or at least to validate them beyond just the initial stages that universities typically work at? I believe the answer is yes.

Looking at startups I was privileged to be a part of, we would generate a great new idea at a university, and the next thing we would do is step out of the university—because universities are not-for-profit, and if you start a for-profit entity, you need to do it off the campus. To launch the startup, the very first thing we needed to do was to reproduce the labs we just left at MIT; refit them with equipment; figure out how to deliver liquid nitrogen or figure out how to set up glove boxes. It’s a huge expense— perhaps a few million dollars and a year and a half of work just to get you to the place where you were when you left MIT.

Why not shorten that journey and make it less expensive by simply saying, “The day after you graduate, come back to MIT.nano as a visiting researcher or research scientist from outside and use our toolsets for a fraction of what it would cost you to reproduce your own”? You can start the journey of validating your startup idea, so that two years later, when you are standing in front of venture capitalists to raise your Round A of funding, you will have a much more baked idea in hand. That also means that the journey from the Round A raise to the deployment of your technology to a million people is not going to take five to ten years. Now it will take three to eight, making it much more amenable to being funded. I think MIT.nano can help us accelerate hardware-technology development in ways that we could not have done before on this campus without the central facility that we are now outfitting.

Q: You recently participated in an event in Washington, DC, reflecting on some potential game-changing technologies in the energy space, along with some of our colleagues from Stanford, to help policymakers appreciate the need to support the underlying research. Where are we today—nationally and internationally—in this arc of innovation and seizing the opportunities that we see from the work in the lab?

A: The new type of solar is coming. In the next five years, we’ll have access to more readily deployable, lighter, very inexpensive solar energy, generating electricity at less than 2 cents per kilowatt-hour. If we are not the ones, as the United States, to lead the solar cell technology discovery and scale-up, some of our economic competitors might embrace that challenge. If and when they mature the new solar technology, we risk being in a dramatically reduced position. Our energy would be more expensive than the energy utilized elsewhere for the production of food and for the support of everyday needs. As a result, we would be disadvantaged, just because we haven’t opened our eyes to the opportunity today: that we should seize the moment and be the lead—as we are presently—in developing the next and the next set of ideas needed to give us this very inexpensive form of electricity.

This article appears in the Spring 2019 issue of Energy Futures.