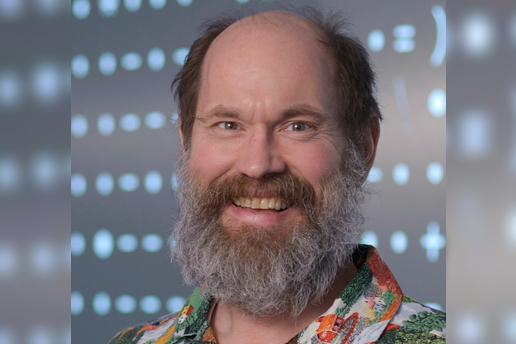

Alexander Slocum, the Pappalardo Professor of Mechanical Engineering and director of the Precision Engineering Group, teaches and conducts research in the area of precision machine design. Precision, he says, has always been in the blood.

“I was one of those kids who grew up and had a problem with drugs: I couldn’t afford them, because I was spending all of my money on my hot rod,” he explains. “When you’ve got a hot rod, you’ve got to make the parts more and more precise to get more horsepower, so you can go faster than the other guy. Some people would refer to it as getting the fat rabbit or the low-hanging fruit.” That, he says, is normal engineering.

Precision engineering is about going for the low-hanging rabbit, so you get the rabbit and the fruit — like killing more than one bird with just one stone. “Simplicity is good,” Slocum says. “God loves engineers. There will never be a shortage of problems.”

Whether it’s a small silicon machine you can’t really see or a giant offshore structure for next-generation floating wind turbines, Slocum finds opportunities to solve many problems at once — especially those for which people are apt to say, “That’s a hard one. It can’t be done.”

Way offshore wind energy

Offshore renewable energy systems, a concept for making offshore wind energetically and economically viable, is one of these. Massive floating wind turbines anchored to giant tubes in the middle of the ocean would store large amounts of excess energy and deliver power on demand.

If the idea sounds implausible, it is matched by Slocum’s quirky, excitable persona and Hawaiian shirts. “Some people may think it’s bad because the water gets deep, but that’s actually also an opportunity. It means you have a free source of how to store the energy,” Slocum says. Instead of using gravity, Slocum’s method — a new spin on the idea of pumped hydro systems — utilizes water pressure from deep beneath the surface of the ocean to generate electricity.

“Because you’ve got all this water sitting on top of them, you put a pump turbine at the bottom. Now, this becomes an upside-down lake,” he explains. “This means when you have extra power that is not needed on land, the pump pumps out the container on the bottom and the water on top is trying to get in. When you open the valve the water will flow back into the container, spinning the turbine, generating electricity.”

Making solar simple

Concentrated solar power on demand, or CSPonD, endeavors to store solar power using heated molten salt while eliminating excess parts that can burn out or corrode. “As an industry person and a hot rod guy,” Slocum says, “I look at it and I say, ‘If any one of those parts goes out, you a need a backup.’”

Slocum’s concept, a more efficient and cost-effective version of that used during the 1970s energy crisis, uses mirrors to reflect sunlight directly onto the salt to heat it. “Inside the tank you have a moving platform such that when the salt layer on the top gets hot, the platform moves down,” he says. “The cold salt below it oozes up the side to mix and get hot. Off the top, you can now draw the hot salt off through your steam generator.”

Harvesting uranium from seawater with wind turbines

Slocum is very new to the very old idea of uranium harvesting from seawater. While terrestrial sources of uranium may die out in 100 years, the amount of uranium per cubic meter of seawater works out to several thousand years’ supply of uranium for nuclear reactors, even if you ran the whole planet on uranium-based electricity.

Slocum came to this through a friend in the nuclear industry, who said, “You know, Alex, we now have better polymers for adsorption of uranium ions onto the polymers. But now we’re facing the issue of the cost of the mechanism of the system to do this. You have to have huge amounts of this polymer to get enough uranium and how are you going to deploy it, pick it up — because you’ve got to pick the polymer up, run it through an acid bath to strip off the uranium and then put the polymer back out.” Slocum, in his 2.75 (Precision Machine Design) class, sponsored by the MIT Energy Initiative, decided to give it a go.

“So, again, we’re looking for — not fruit — ripe fruit trees and we’re not looking for a flock of rabbits,” he says. “We’re looking for rabbits in the orchard.” What his group came up with were offshore wind turbines. He wondered whether you could design a system that hangs like a skirt on the wind turbine and have that system, with ropes of the polymer, somehow circulate. The station for processing and stripping the uranium could be based right there in the wind turbine. Boats could come out to the wind turbine to service them and the uranium-stripping machine.

“Environmentally, this is a very desirable technology,” Slocum explains. “You want to be able to make available, to the world, the ability for anyone who has a coastline to harvest their own uranium. That way they will not be motivated to take their spent fuel from their reactor and reprocess it. So it can be a really good way of promoting nonproliferation.”

History has a way of repeating itself, Slocum says: “Before you had MIT, you had people who wanted to do stuff: machines. They went and served an apprenticeship. Then universities, technical universities, became a little more formalized.”

He says the value of science and understanding engineering became apparent. The pendulum started to swing, but may have swung too far, distancing academics from their roots as engineers. “As you can tell by my formality, I’ve never really strayed too far. I learned that when you have a real problem and you solve it — even if it’s just by intuition, you wonder, ‘Man, I got it to work, but I wonder why that worked?’ Let’s figure that out.”