Since 2014, following a tremendous crash in which oil prices dropped by half, oil and gas firms have frequently struggled to break even on new wells in the tight oil and shale gas basins of the United States. Continuing low prices have led to substantial uncertainty about future production levels of unconventional oil and gas and the long-term economic viability of these resources.

The ongoing competitiveness of these resources depends on improving the productivity of new tight oil and shale gas wells, which has in part been enabled by new technological advances in drilling techniques and hydraulic fracturing. However, according to MIT research, these gains may be significantly overstated because industry “sweet-spotting”—drilling in the most productive locations in a field—is not being properly considered in current production forecasts.

Sweet-spotting, also called “high-grading,” might be a profitable strategy in the short-term, but will not be possible once these areas have been exploited. Therefore, it is critical to be able to accurately forecast future productivity levels by separating the role that technology plays in well design from the geological influence inherent in sweet-spotting strategies.

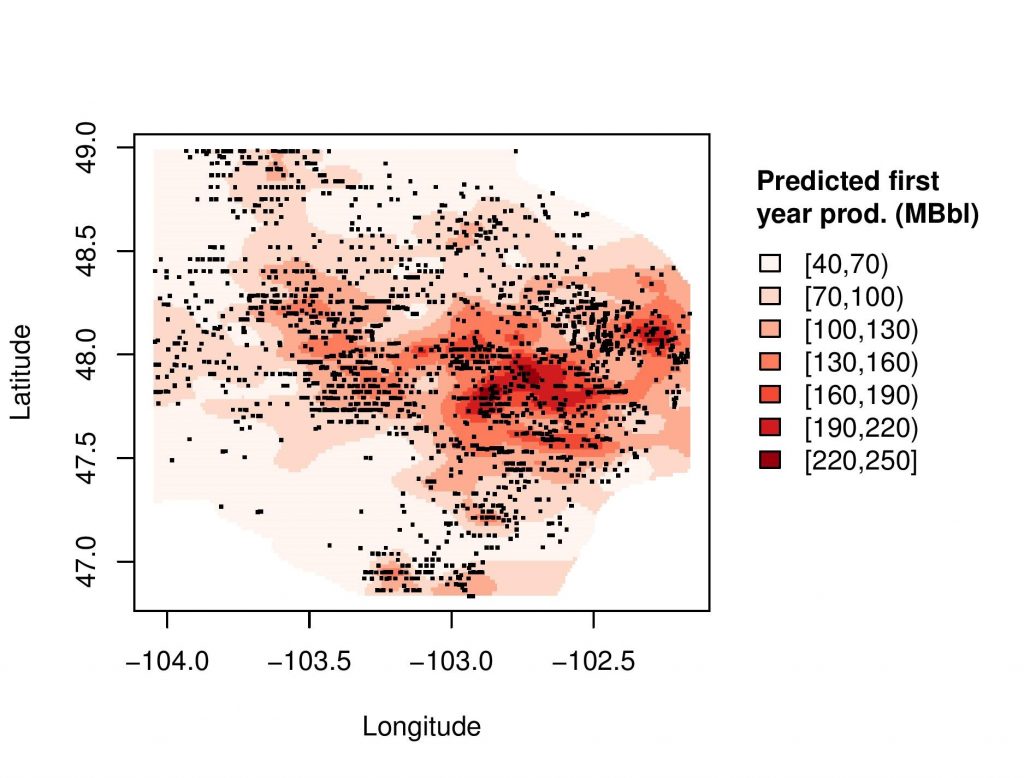

This map depicts the expected first-year production of tight oil wells located within the Bakken formation in North Dakota using the regression-kriging approach—a statistical modeling approach that accounts for spatial variability at a high resolution. There has been a shift toward drilling activity in the core (dark red) areas, a practice known as “sweet-spotting.” Models that are currently used in industry practice cannot capture this level of spatial variability. Photo: Courtesy of the researchers.

In a new paper in Applied Energy, Justin Montgomery, a graduate student in civil and environmental engineering who is also a MITEI researcher, and Francis O’Sullivan, MITEI’s director of research, describe the application of a statistical approach that can reliably distinguish between the impact that changes in well location and technology have on the productivity of a well.

Today, many industry and government entities rely on simpler models for productivity forecasting that have a limited ability to accurately distinguish between the influence of geology and technology. “There has not been a rigorous attempt to disentangle the effects of technology and sweet-spotting,” says Montgomery. “We realized that there was an opportunity to both provide a better understanding of what this balance has been in a particular tight oil basin and at the same time present a methodology that can be used in other basins.”

Montgomery and O’Sullivan tested five different models using data combed from a 42-month period and nearly 4,000 wells drilled into North Dakota’s Middle Bakken and Three Forks formations, the primary oil- and gas-producing layers of the Williston basin. In recent years, thousands of wells have been drilled into these stacked rock layers and well designs have rapidly evolved, making it an ideal region for the study.

Beginning with models that are based on current industry practice—a nonspatial regression model, a fixed effects model, and a surface trend analysis model—the researchers found that these approaches each offered different levels of complexity to control for location. This is critical to note since important geological properties in shale and tight reservoirs vary considerably over even short distances, and what all of these approaches imply is that the variation in these spaces can be neglected at a certain point without overly influencing the results.

Montgomery and O’Sullivan discovered that this isn’t necessarily true. These models, one of which is currently relied upon by the U.S. Energy Information Administration for developing their Annual Energy Outlook forecasts, have a tendency to significantly overestimate the impact of technology because they are not flexible enough to account for these short-distance locational variations present in the data. In the Bakken and Three Forks of North Dakota, for instance, they found that half of the gains in average well productivity were actually due to changes in where companies were drilling wells rather than how they were drilling them. This means that current forecasts for future production and cost of tight oil and shale gas resources in the United States may be overoptimistic due to unrealistic expectations of future technology-driven productivity gains—an important consideration for any transition to a lower-carbon future where natural gas plays a bridging role in the power sector.

Looking for ways to separate out the influence of technology from the location, Montgomery and O’Sullivan turned to the earth sciences. Models to estimate the amount of snow on a mountain or the properties of soil in different locations, for example, provided a helpful parallel. The earth science researchers in these cases sought to make sense of the hidden spatial patterns affecting their data, and their methods, therefore, provided a much more statistically rigorous template for Montgomery and O’Sullivan to follow than what is currently being used with oil and gas wells.

The researchers propose using two popular earth science approaches in their own research that have never before been used in well productivity modeling: a spatial error model and regression-kriging. These significantly improve prediction accuracy, because they are able to account for the variance in location at a much higher resolution.

“Another byproduct of this model is that it is a very powerful predictive model and you can essentially estimate what the expected productivity would be at any location in the field with a realistic technology design,” says Montgomery. “It’s a very challenging economic situation for developing wells in these fields right now, but this research should help both policymakers and commercial entities better understand what can be expected from these important resources going forward.”

This research was supported by the MIT Energy Initiative.