As many areas of the world continue to experience severe droughts, the challenge of dwindling fresh water supplies becomes more real. That challenge is only expected to increase with changes brought on by climate change and population growth. To combat this challenge, MIT researchers evaluate the potential of cheaper, smaller and faster desalination plants in a new study.

“The world has a virtually limitless supply of seawater,” says David Cohen-Tanugi, the lead author of the study and an MIT graduate student in the Department of Materials Science & Engineering. “But the process used to filter that seawater is too expensive, and the desalination plants take up valuable oceanside real estate. To make desalination widespread, which is so critical for our future, we need to reduce the cost.”

In the study released recently in Energy & Environmental Science, Cohen-Tanugi and his co-authors—MIT PhD students Shreya Dave and Ronan McGovern, and Professor John Lienhard, Director of the Center for Clean Water and Clean Energy at MIT and KFUPM, and Professor Jeffrey Grossman of the Department of Materials Science & Engineering—find that if plants use a more permeable filter, such as a graphene membrane, to purify water, the plant’s energy consumption could be reduced by up to 46 percent. In the process, such improved technology would spur a new generation of desalination plants that are more energy-efficient, as well as smaller and faster.

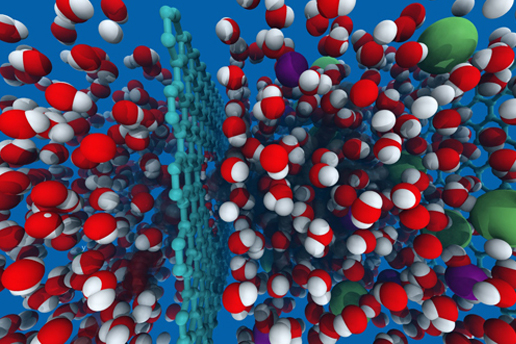

The study builds on previous work in which Cohen-Tanugi and Grossman modeled the use of sheets of graphene to filter water. The very thin, yet strong, material has small pores that can be “tuned” to allow more water to pass through, while still blocking the impurities. In contrast to current polyamide-based filters, the researchers found that graphene filters could drastically reduce both the amount of salt in the purified water and the energy required for desalination.

- (That research was ranked by Smithsonian as one of the Top 5 Surprising Scientific Milestones of 2012.)

“The thinner your filter, the more water that will go through, and the less energy you will consume in the process,” Cohen-Tanugi says.

The researchers knew then that the new material would lead to a far more efficient and possibly less expensive process than used in existing desalination systems. But by how much?

Their latest study answers this question. When tripling the permeability of the filters used in the desalination plant, the researchers’ models show such increased permeability would allow the plant to use 15 to 46 percent less energy to filter salt and brackish water, respectively. It would also allow for the use of 44 to 63 percent fewer pressure vessels.

“Our results essentially showed that more permeable filters require fewer pressure vessels, meaning future desalination plants could become smaller and cheaper,” Cohen-Tanugi says. “Additionally, we discovered that these more permeable filters are more efficient when using brackish water—such as in groundwater—as opposed to seawater. So not only will we be able to build smaller plants going forward, we’ll also be able to build them further away from the sea.”

The research was supported by the MIT Energy Initiative Seed Fund Program, as well as the NSF Graduate Research Fellowship Program, the Fulbright International Science and Technology Award Program, the International Desalination Association, the Channabasappa Memorial Scholarship, the MIT Martin Family Sustainability Fellowship Program and a generous gift by the Douglas C. Spreng Fund.